Fameccanica has recently presented at the 25thChina International Disposable Paper Conference new solutions for pant diapers for baby, feminine care and incontinence, with improved breathability, softness and fit. While absorbency is currently considered as a must property when buying a product, there’s an increase of attention on higher breathability, softness and fit.

The rise of pant diapers industry

The recent years have seen an evident growth of the pant diapers market. This trend covers the key Asian regions and, according to a recent report from China National Household Paper Industry Association, in 2016, pull-up diapers held around 20% sales volume of baby diapers, almost 5% higher than previous year.

Also, according to the Association, the growth rate of pant diapers is higher than the average of the diaper industry. All big players and multinationals have increased the presence of their pant-versions in their portfolio. This is valid not only for baby but also for feminine care and adult incontinence.

Furthermore, other statistic resources show that China baby pull-up pants industry is rising dramatically. From 2011 to 2015, China's retail sales of baby pants increased from 700 million yuan to 3.2 billion yuan. This means a compound annual growth rate of 44%, which is higher than the overall baby diaper market 15% CAGR in the same period. The estimated annual growth rate, from 2016 to 2020, of retail sales volume of China baby pants is 27%.

New opportunities for better products in the pant-style diapers segment

Fameccanica identified 3 key areas of improvement. First, there’s a focus on COMFORTresulting from breathability. Waist band solutions with film - or with threads, have been explored and updates on options for in-line perforation of nonwoven backsheet have been provided.

The second focus is on tactile perception, which normally means a request for product SOFTNESS. There are three areas of attention:

- new technical solutions for soft side seams

- how softness may be improved with the appropriate waist band solutions with film - or with threads

- solutions for three-dimensional laminates.

Finally the FIT characteristicthat offers three opportunities:

- thin cores with appropriate levels of absorption as a result of different core versions

- less wrinkles on waist band, and

- thin side seams

Comfort through increased breathability

A first solution based on Fameccanica patent EP3092997B1 provides the removal of glue on the waistband elastic application. Elastics are incapsulated in the waistband. The elimination of the glue between the waistband nonwoven layers, provides improved breathability to the product.

Then there’s the case of products having elastic film waistband instead of threads. Films are normally non-breathable or with very low breathability, and in such case, there’s Fameccanica solution for in-line sealing and simultaneous film perforation. This solution provides improved breathability as it creates holes during the in-line lamination. Fameccanica can propose different versions of this film laminate, using different sealing patterns for aesthetic purpose.

The third solution for increased breathability is the in-line perforation of the nonwoven backsheet. Perforated materials provide the feeling of increased breathability. It is possible to find several premade materials in the market. The advantage of Fameccanica solution, compared with pre-mades, is cost saving. In fact, this process is done in-line by the machine and reduces the cost in comparison with commercial materials.

|

|

|

Figure 1- Glueless elastic waistband solution based on Fameccanica patent EP3092997B1 |

Figure 2- Pull on with breathable film lamination (Fameccanica process) |

Softness through better side seam

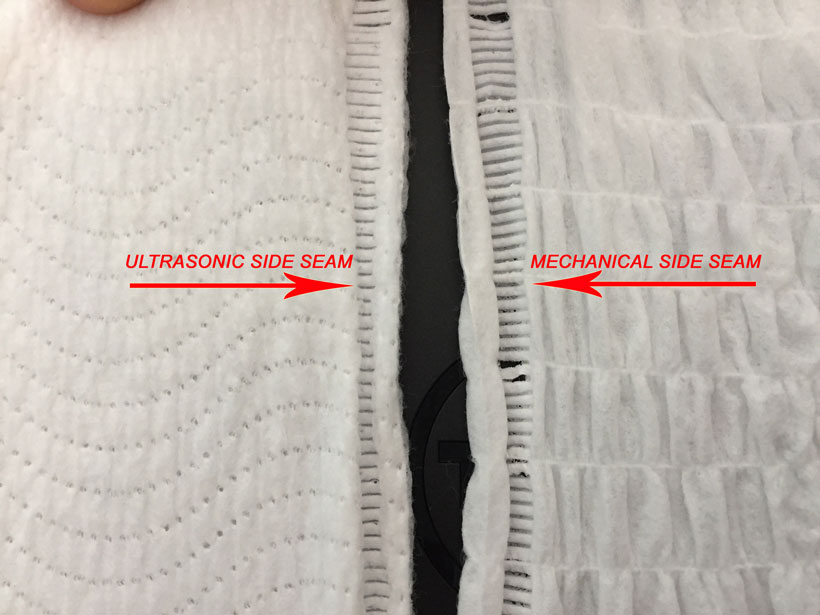

A solution for increased softness is related to the side seam of pants, generally obtained with mechanical sealing, however, ultrasonic sealing proved to be a better way to achieve a softer application. This solution provided by Fameccanica on machine models producing up to 650 pieces per minute.

For higher speeds, up to 900 pieces per minute, Fameccanica has a second solution which is a recent unique technological solution named MHR. This solution provides the softest side seams, along with the strongest bonding ever, and impacts also discreteness and fit, as it reduces the dimension of side seams thanks to a precise final product cutting between the sealing lines.

The third solution for increased softness includes 2 different opportunities for waist bands through the elimination of glue. These solutions, in fact, have an impact on softness; as the presence of glue, in many cases, gives a stiff feeling, the elimination of glue makes it possible to have a positive impact and higher softness.

|

|

Figure 3- Ultrasonic side seam |

Softness through 3d laminates

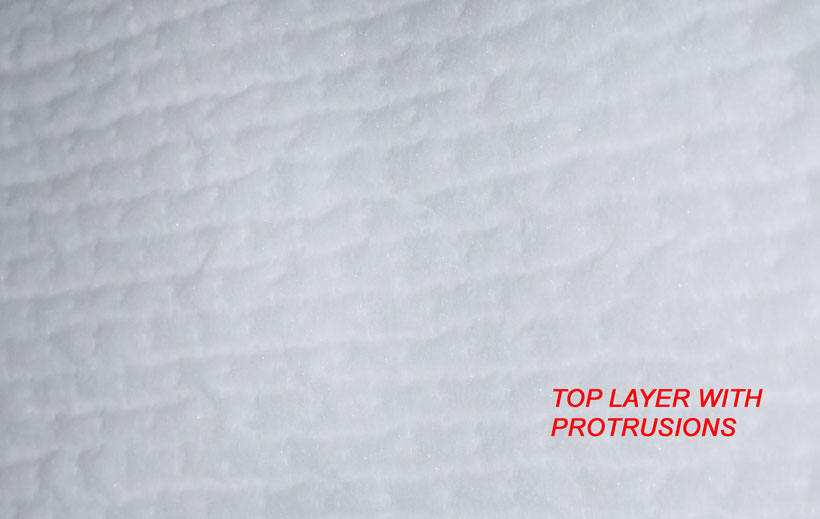

This is a solution that creates a 3D effect with material lamination, and is a new process covered by a patent application.

Such Fameccanica 3D laminate provides a significant increase of softness and caliper vs the 2 initial flat layers. Thickness increase is normally 3 times the initial layer, and the different aesthetics on the two sides (protrusions and channels) shouldn’t be underestimated.

|

|

|

Figure 4- Top layer with protrusions |

Figure 5- Opposite side with channels |

Fit through thin cores

Ultrathin absorbent cores provide perfect fit. Fameccanica has two proposals for the manufacturing of thin absorbent cores: one with a high percentage of fluff and one that is totally fluffless.

The first has two different forming systems designed to accept a wide range of SAP/fluff ratios. The second is characterized by the following key advantages: breakthrough acquisition, breakthrough integrity, superiority in dry and wet conditions and thickness depending on the grammage and thickness of the fibrous material encapsulating the SAP.

Fit through less wrinkles

This solution for better fit is related to the use of film in waistbands, such as the laminated film that was introduced before, when talking about breathability. Laminated film, in fact, impacts discreteness, as it significantly reduces wrinkles.

The market demand is for flat appearance of the waistband and this can be achieved by replacing the traditional elastic threads with film materials.